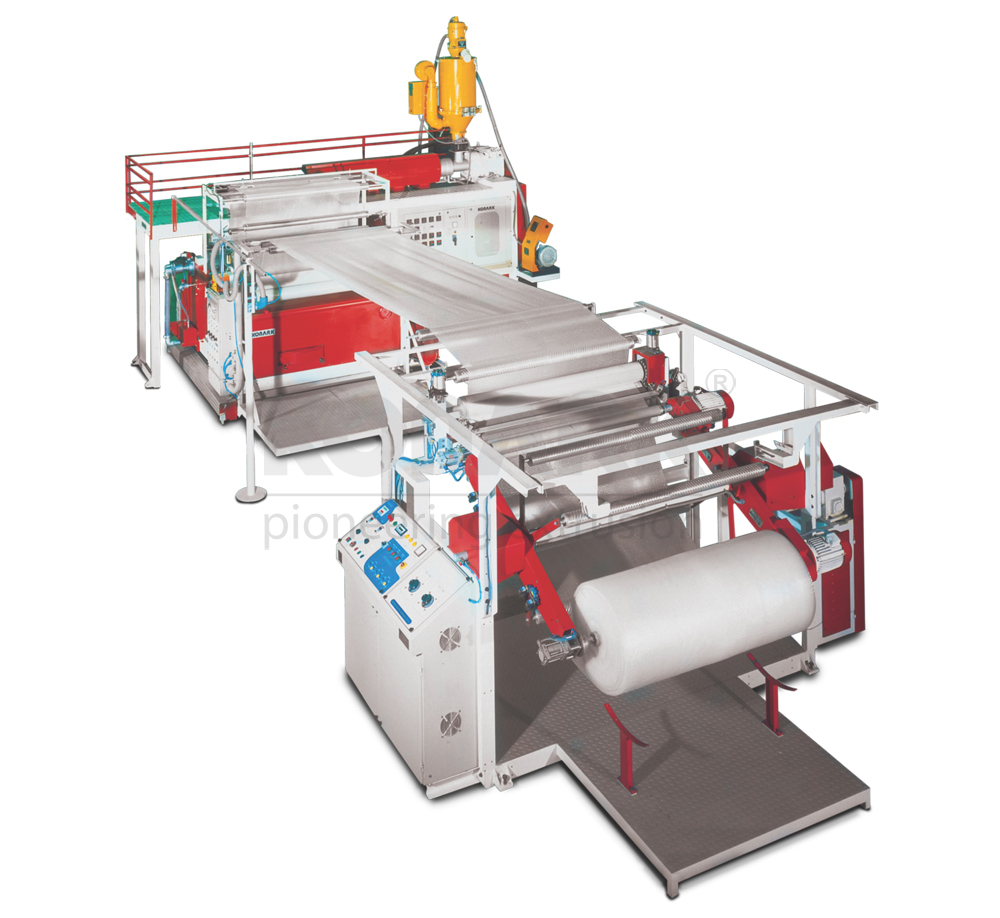

Air Bubble Sheet Extrusion Line

- Width of Sheet : 1000 mm / 1500 mm / 2000 mm / 3000 mm

- Output Capacity : 80 Kg/Hr to 250 Kg/Hr

- Sturdy constructed lines suitable for LDPE/LLDPE Air Bubble Sheet Extrusion

- High productivity with less power consumption

- Output range starting from 80 Kgs/Hr to upto 250 Kgs/hr

- Auto Hopper loader cum dryer unit

- Smooth Feed type Nitrided Barrels

- Simple or Barrier type Nitrided Screws

- Helical gear box with inbuilt thrust bearing

- Lever type filter changers

- Uniquely designed double lip ‘T’ die ensuring uniform flow distribution

- Specially designed bubble forming roller

- PLC based fully automatic turret type winding system

- High density ceramic type band heaters

- SSR based all heating zones

- Single point synchronization of whole line with AC motors and AC invertor drives

- Third layer attachment

- Fourth layer attachment

- Hydraulically operated filter changer

- Electronic Item Packing

- Crockery Packing

- Glass Item Packing

- Home Appliances Packing

- Handicraft Packing

- Industrial Item Packing

| Model | KAB/80-1000 | KAB/90-1500 | KAB/90-2000 |

| Material To Be Processed | LDPE, LLDPE | LDPE, LLDPE | LDPE, LLDPE |

| Screw Dia | 80 mm | 90 mm | 90 mm |

| Barrel Feed Type | Smooth Feed | Smooth Feed | Smooth Feed |

| Air Bubble Sheet Width | 1000 mm | 1500 mm | 2000 mm |

| Maximum Output | 80 Kg/Hr | 125 Kg/Hr | 150 Kg/Hr |

| Die | Dual Lip T – Die | Dual Lip T – Die | Dual Lip T – Die |

| Winder | Fully Auto Turret Rewinder | Fully Auto Turret Rewinder | Fully Auto Turret Rewinder |

| Machine Connected Load | 88 KW (117 HP) | 118 KW (157 HP) | 133 KW (177 HP) |

| Dimensions ( L x W x H ) Apprx |

30 x 15 x 18 Feet | 45 x 25 x 18 Feet | 50 x 30 x 20 Feet |

*Customized Air Bubble Sheet Line for 3 Mtr sheet width are also available as per customer requirement.

*All above specifications are just for an idea and subject to change arising out of continuous product change and improvement.