4-Extruder 5-layer Pod Blown Film Extrusion Line

- Film Structure : Five Layer Non Barrier Film

- Processing Materials : LLDPE/mLLDPE/LDPE/HDPE

- Layer Ratio : 1:2:4:2:1

- LayFlat Width : Up To 1250 mm

- Output Capacity : Up To 200 Kgs/Hr

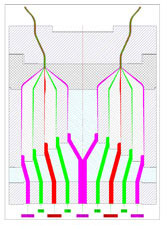

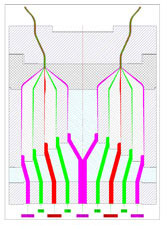

- 4-Extruder 5-Layer Non Barrier Film Structure

- Less power consumption due to single extruder for tie layers

- Wide option for various grade raw material recipe

- Thick core & thin skin & tie layers thus cost saving of raw material

- Better film with high mechanical property

- Option for down gauging of film structure

- Less space requirment

- 100% indigenously designed & developed barrier type Screws

- Nitrided groove feed barrel made out of special nitro alloy steel for long life

- Helical gear box with inbuilt thrust bearing

- Lever type filter changer for each extruder

- 100% indigenously designed 4-extruder 5-layer spiral type die ensuring better flow distribution and better thickness control

- High velocity aluminum cast dual lip air cooling ring for better output

- Motorized operated calibration basket

- Horizontal type reversing haul-off unit for gauge randomization

- Web aligner system

- Corona treatment unit

- Trimming arrangement with trimming blower

- Two station winder unit with auto change over

- High density ceramic band heaters

- SSR based all heating zones

- AC motors and AC invertor drives

- PLC based line control

- Gravimetric Dossing Unit

- Air Chiller Unit

- Lamination Film

- Milk Film

- Machine Grade Stretch Film

- Heavy duty Shrink Film

- Courier Bag Film

- Snack & Flour Packing Film

Copyright © 2018 Konark Plastomech Pvt. Ltd. All rights reserved.