ABA Three Layer Blown Film Extrusion Line

- LayFlat Width : 150 mm to 1500 mm

- Output Capacity : 40 Kg/Hr to 150 Kg/Hr

Allows to produce three layer film by using maximum % of recycled & calcium filled materials in middle (B) layer and virgin material in outer skin (A) layers

Produce three layer films with higher resistance & better quality with significant reduced raw material cost

Deliver higher profitability with higher output with lower power consumption

Quick & maximize return on investment

- Compact dimensions results in minimum space requirement

- Output range starting from 40 Kgs/Hr to upto150 Kgs/hr

- Grooved Feed type Nitrided Barrels

- Nitrided Screw-Barrel made of special alloy steel for longer life

- Helical gear box with inbuilt thrust bearing

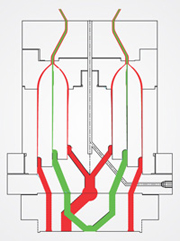

- Uniquely designed spiral type of Co-Ex- ABA die suitable for HM-HDPE or LD-LLDPE materials

- Uniquely designed Air Cooling Ring for higher output

- High velocity air ring blower with AC invertor drive

- Bubble Calibrating Basket / Iris Ring

- Universal gusseting arrangement

- Embossing roller attachment

- With or without vertical type oscillating haul-off unit for gauge randomization

- Web aligner system

- Single station / two station surface type rewinder

- Centre & Side slitting arrangement

- High density ceramic type band heaters

- SSR based all heating zones

- Single point synchronization of whole line with AC motors and AC invertor drives

- LDPE-LLDPE Attachment

- Lever type Filter Changer

- Semi / Fully automatic Winder with PLC Controls

- Corona Treater Unit

- Air winding shaft

- Auto Hopper Loader cum Dryer Unit

- Film for Carry Bag, Shopping Bag, D Cut Bag, Grocery Bag etc.

- Film for Garbage Bag / Trash Bag

- Film for Liners

- Film for general purpose loose packing

| Model | KML-A/35-40-G | KML-A/40-47-G | KML-A/47-55-G |

| Material To Be Processed | HM, HDPE | HM, HDPE | LDPE, LLDPE |

| Screw Dia | Extruder A – 35 mm | Extruder A – 40 mm | Extruder A – 47 mm |

| Extruder B – 40 mm | Extruder B – 47 mm | Extruder B – 55 mm | |

| Barrel Feed Type | Groove Feed | Groove Feed | Groove Feed |

| Layflat Film Width Range | 250 to 600 mm | 350 to 900 mm | 800 to 1300 mm |

| Film Thickness Range | 20 to 100 micron | 20 to 100 micron | 20 to 100 micron |

| Maximum Output | 70 Kg/Hr | 90 Kg/Hr | 120 Kg/Hr |

| Die | Co-Ex ABA Die | Co-Ex ABA Die | Co-Ex ABA Die |

| Winder | Single Station Surface Winder | Single Station Surface Winder | Double Station Surface Winder |

| Machine Connected Load | 52 KW (69 HP) | 64 KW (85 HP) | 98 KW (85 HP) |

| Dimensions ( L x W x H ) Apprx |

10 x 10 x 15 Feet | 12 x 12 x 18 Feet | 25 x 12 x 18 Feet |

| Optional Attachment | LDPE, LLDPE Attachment | LDPE, LLDPE Attachment | HM, HDPE Attachment |

| Rotating Haul Off Unit | Rotating Haul Off Unit | Rotating Haul Off Unit | |

| Double Station Winder | Double Station Winder |

*All above specifications are just for an idea and subject to change arising out of continuous product change and improvement.