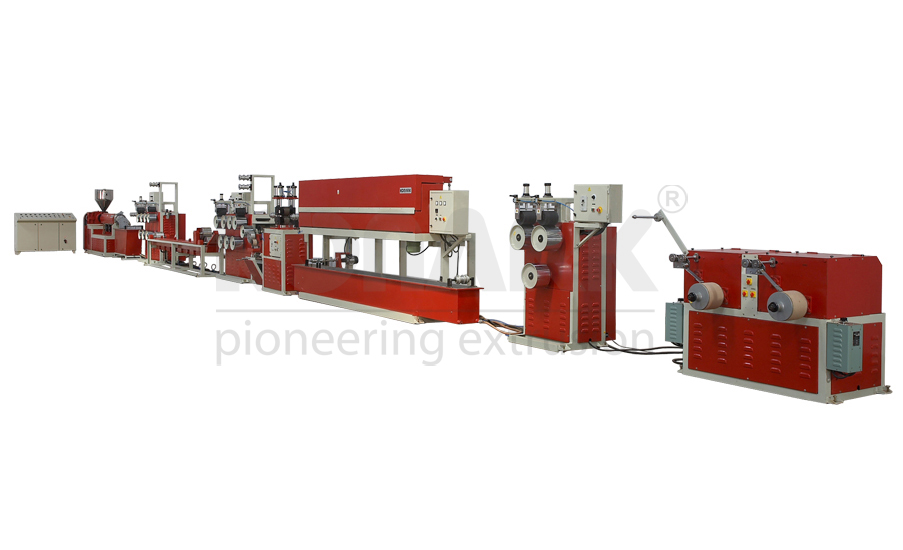

PP Semi Auto / ABA 3 Layer Strapping Band Extrusion Line

- Strap Size : 9 mm / 12 mm / 16 mm / 19 mm

- Output Capacity : 35 Kg/Hr to 100 Kg/Hr

- Models suitable for Semi Auto Heat Sealable Straps.

- Output range starting from 35 Kgs/Hr to upto 100 Kgs/hr

- Smooth Feed type Nitrided Barrels

- Nitrided Screw-Barrel made of special alloy steel for longer life

- Helical gear box with inbuilt thrust bearing

- Specially designed strapping die head ensuring uniform flow distribution

- Individual die inserts for different strap sizes

- Lever type filter changer

- Orientation hot water tank for uniform strap stretching

- Unique stabilizing hot air oven design with chilled water tank

- Embossing roller assembly

- Inline single colour strap printing unit

- Specially design winder for semi automatic strap application

- High density ceramic type band heaters

- SSR based all heating zones

- Single point synchronization of whole line with AC motors and AC invertor drives

- Hydraulic operated filter changer

- Auto Hopper Loader cum Dryer unit

- Servo Based Electronic Winder

- Wooden / Corrugated Box Packing

- Textile Cloth Packing

- Paper Packing

- Cartoon Packing

| Model | KSBX/65 | KSBX/75 | KSBX/90 |

| Material To Be Processed | PP | PP | PP |

| Screw Dia | 65 mm | 75 mm | 90 mm |

| Barrel Feed Type | Smooth Feed | Smooth Feed | Smooth Feed |

| Strap Sizes & Lines | 9 mm – 2 Lines | 9 mm – 3 Lines | 9 mm – 4 Lines |

| 12 mm – 2 Lines | 12 mm – 3 Lines | 12 mm – 4 Lines | |

| 16 mm – 1 Line | 16 mm – 2 Line | 16 mm – 3 Line | |

| 19 mm – 1 Line | 19 mm – 1 Line | 19 mm – 2 Line | |

| Maximum Output | 60 Kg/Hr | 80 Kg/Hr | 100 Kg/Hr |

| Winder | Four Station Winder | Five Station Winder | Six Station Winder |

| Machine Connected Load | 77 KW (103 HP) | 110 KW (147 HP) | 140 KW (187 HP) |

| Dimensions ( L x W x H ) Apprx |

80 x 8 x 8 Feet | 90 x 8 x 8 Feet | 110 x 8 x 8 Feet |

*Customized ABA Type Strapping Band Extrusion Lines are also available as per customer requirement.

*All above specifications are just for an idea and subject to change arising out of continuous product change and improvement.