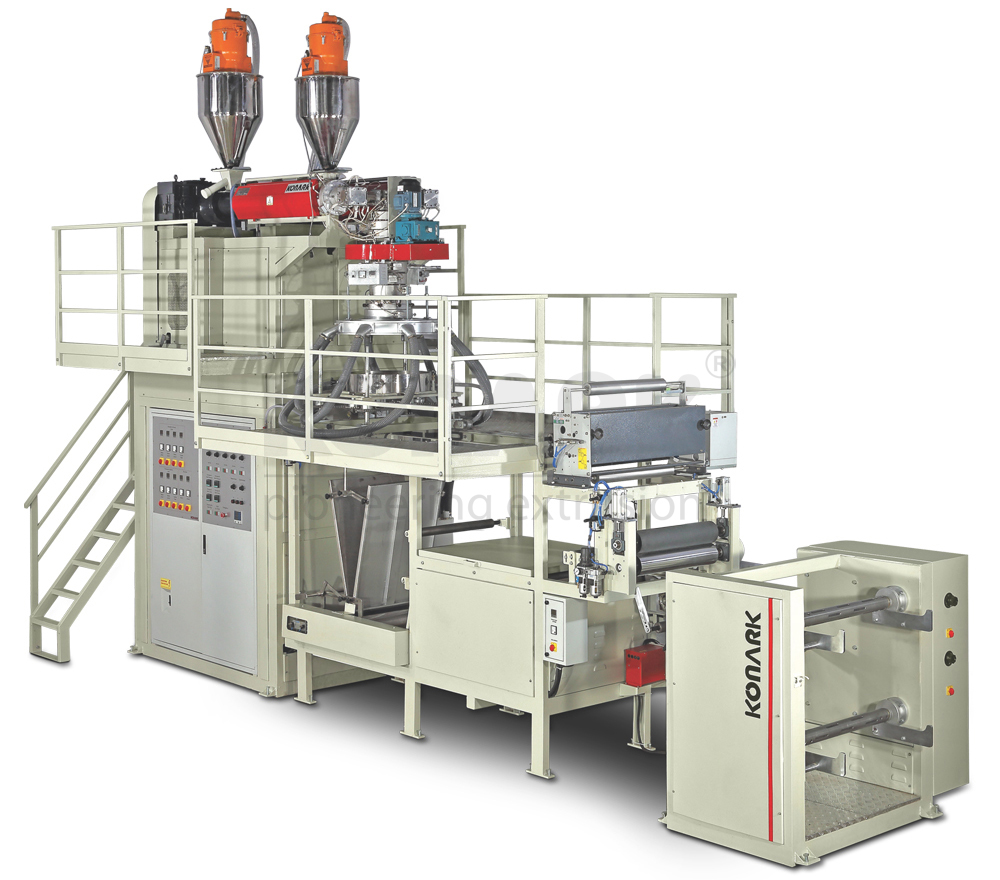

TQ PP Water Quench Film Extrusion Line

- LayFlat Width : 40 mm to 1000 mm

- Output Capacity : 25 Kg/Hr to 150 Kg/Hr

- Sturdy compact design

- Output range starting from 25 Kgs/Hr to upto 150 Kgs/hr

- Grooved Feed or Smooth Feed type Nitrided Barrels

- Nitrided Screw-Barrel made of special alloy steel for longer life

- Helical gear box with inbuilt thrust bearing

- Uniquely designed spiral type die ensuring uniform flow distribution

- Uniquely designed air cooling ring with high velocity air ring blower

- Ghan metal casted sizer

- Alluminum casted sizer water bath

- Manual / Motorized water bath up-down system

- Stainless steel made nip roller, film flatterning board & Water tank

- High efficient online drying unit

- Center type sturdy rewinder

- High density ceramic type band heaters

- SSR based all heating zones

- Single point synchronization of whole line with AC motors and AC invertor drives

- Continuous 360° rotating die

- Lever type filter changer

- Corona Treater unit

- Auto Hopper Loader cum Dryer unit

- Air winding Shaft

- Garment & Textile Packing

- Hosiery Product Packing

- Backery Product Packing

- Vegetable & Fruit Packing

- PP Lamination Pouch Film

| Model | KPP/40-S | KPP/40-G | KPP/51-S | KPP/47-G | KPP/55-S | KPP/51-G | KPP/65-S | KPP/55-G |

| Material To Be Processed | PP | PP | PP | PP | PP | PP | PP | PP |

| Screw Dia | 40 mm | 40 mm | 51 mm | 47 mm | 55 mm | 51 mm | 65 mm | 55 mm |

| Barrel Feed Type | Smooth Feed | Groove Feed | Smooth Feed | Groove Feed | Smooth Feed | Groove Feed | Smooth Feed | Groove Feed |

| Layflat Film Width Range | 40 to 250 mm |

50 to 450 mm |

75 to 450 mm |

150 to 500 mm | 150 to 600 mm | 200 to 750 mm | 200 to 750 mm | 300 to 850 mm |

| Film Thickness Range | 20 to 100 micron | 20 to 100 micron | 20 to 100 micron | 20 to 100 micron | 20 to 100 micron | 20 to 100 micron | 20 to 100 micron | 20 to 100 micron |

| Maximum Output | 25 Kg/Hr | 40 Kg/Hr | 40 Kg/Hr | 50 Kg/Hr | 50 Kg/Hr | 75 Kg/Hr | 55 Kg/Hr | 100 Kg/Hr |

| Die | Stationary Die | Stationary Die | Stationary Die | Stationary Die | Stationary Die | Stationary Die | Stationary Die | Stationary Die |

| Sizer Material | Ghan Metal | Ghan Metal | Ghan Metal | Ghan Metal | Ghan Metal | Ghan Metal | Ghan Metal | Ghan Metal |

| Winder | Two Station Center Winder | Two Station Center Winder | Two Station Center Winder | Two Station Center Winder | Two Station Center Winder | Two Station Center Winder | Two Station Center Winder | Two Station Center Winder |

| Machine Connected Load | 24 KW (32 HP) |

29 KW ( 39 HP) |

30 KW (40 HP) |

31 KW (41 HP) |

35 KW (47 HP) |

45 KW (60 HP) |

42 KW (56 HP) |

52 KW (69 HP) |

| Dimensions ( L x W x H ) Apprx |

20 x 5 x 9 Feet |

20 x 5 x 9 Feet |

25 x 5 x 10 Feet |

25 x 5 x 10 Feet |

25 x 6 x 11 Feet |

25 x 6 x 12 Feet |

25 x 6 x 12 Feet |

30 x 10 x 14 Feet |

| Optional Attachment | Rotating Die | Rotating Die | Rotating Die | Rotating Die | Rotating Die | Rotating Die | Rotating Die | Rotating Die |

*Customized Two Layer TQ PP Blown Film Extrusion Plants are also available as per customer requirement.

*All above specifications are just for an idea and subject to change arising out of continuous product change and improvement.